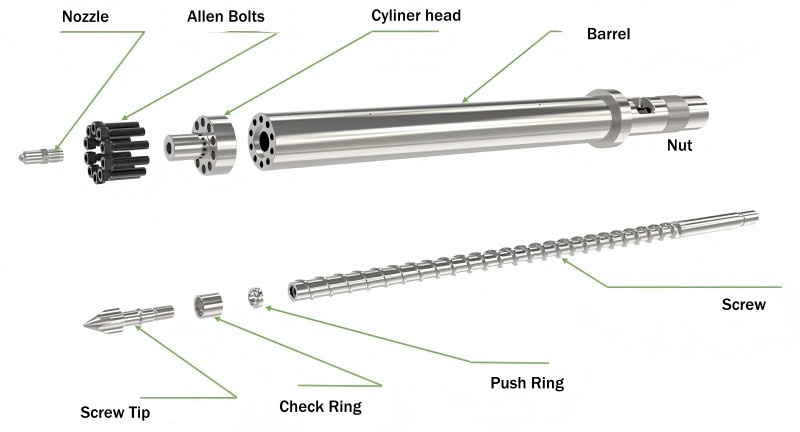

Accessories: Screw head, Rings, Flange End cap, Nozzle Tip Base Materials: SACM645,SCM440,SKD61 Process: Nitrided, Chrome-Plating, Bimetallic Suitable for: PP, PE, ABS, PET, PVC, PS ... Features: High Wear-Resistance, Fast Delivery, Low Cost Delivery time: 20-25 days Warranty Time: 12 Months

The Complete Injection Molding Parts We Make:

Screw Type | Specification | Plastics Application | Characteristics |

Bimetallic Screw | SACM645 Steel, top spray weld Tungsten carbide-based alloy | Transparent products, PA6, PA66 and other Engineering materials with fibers | Surface hardness is about HRC60°, Alloy layer thickness is 0.8-2.5mm, and it is wear-resistant |

Chromed Screw | plated with Chromium, Titanium | PC/PMMA/PET transparent material,corrosive PVC | The coating is 0.03-0.06mm thick, the hardness is about HRC60°, and it is corrosion resistant |

Stainless Steel Screw | Overall quenching hardening | High corrosion-resistanct | The overall hardness is about HRC 55°, and it is corrosion resistant |

SKD61 Screw | SKD61 material, special process treatment | General Purpose Plastics | Good toughness and strong torsion resistance |

Nitride Screw | SACM645 substrate, nitrided | PP, ABS, PS, AS, PVC and other common plastics | Nitriding layer depth is 0.5-0.8mm, and the hardness is HV980-1080 |

Barrel Material | Process | Hardness | Application | Characteristic |

SACM645/38CrMoala | Nitriding | HV 950-1000 | General Plastics such as PP、PE、ABS、PS、AS、PVC etc | Stable and the cost is low, the corrosion/wear resistance are average. |

SCM440/42CrMo | Bimetallic | HRC 58-62 | Engineering plastics (such as PA, PBT), PPS, LCP and other highly corrosive or filler plastics with glass fiber | Excellent wear /corrosion resistance,suitable for high wear and corrosive plastics |

Stainless Steel (9Cr18MoV) | Hardening | HRC 55 | Suitable for food, medical and other occasions with hygiene requirements, or for processing some plastics with special corrosiveness | Good corrosion resistance, meet hygiene standards. |

Materials & Treatments:

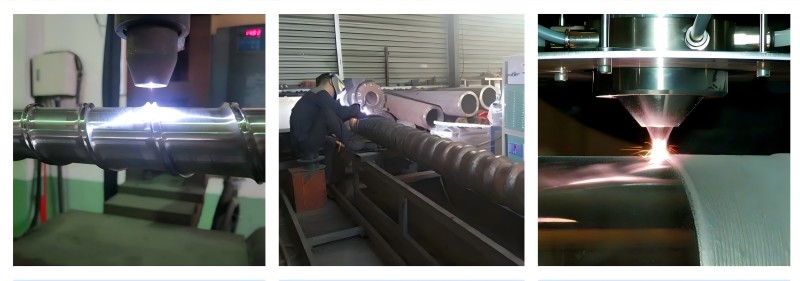

⁕Bimetallic Process :

Basis Materials: SACM645, SACM440, SKD61, SKD11

Hardness: 53-58 HRC

Coating Thickness: 1.5-2.0mm

Allication: Plastic Recycling ≤2 Times, Plastics With Glass Fiber≤35%

Wear resistance: ★★★★★

Corrosion resistance: ★★★

Basis Materials: SACM645, SACM440, SKD61, SKD11

Chrome Thickness: 0.02-0.08mm

Hardness of Chrome: >700 HV

Finish Grade: Ra ≤0.4

Allication: PVC and other high corrosive plastics

Wear resistance: ★★

Corrosion resistance: ★★★★★

⁕Full Hardened Process:

Basis Materials: DC53, D2, M2, SKD61, SKD11 ...

Chemical Composition: C, Si, Cr, Mn, Mo, V, Ni

Hardness: SKD61(HRC56-58), DC53( 62-63 HRC)

Application: PP PA LCP, POM, PPA, PBT, PC, PPS, PEI, PEEK with Glass Fiber ≤50%

Wear resistance: ★★★★★

Corrosion resistance: ★★★★★

![]()

FAQS:

Q: When will you arrange the production?

A: We can arrange production soon after order & drawings confirmation

Q: What is your delivery time ?

A: Standard delivery time is 20-25 days, if the screw's diameter is less than 50mm, the delivery time can be 15-20 days

Q: What is your accepted payment type?

A: T/T

Q: What logistic forwarder do you usually work with?

A: EMS, TNT, UPS, FEDEX and other high-efficient logistric forwarders

Q: What is your warranty Time ?

A: 12 months when shipment on board

![]()

Customers Machinery List :

| Haitian Injection Molding Systems | ChenHsong Injection Molding Systems | Hwamda Injection Molding Systems |

| Yizumi Injection Molding Systems | Nissei Injection Molding Systems | TOYO Injection Molding Systems |

| Toshiba Injection Molding Systems | Borche Injection Molding Systems | Haida Injection Molding Systems |

| JSW Injection Molding Systems | Arburg Injection Molding Systems | Engel Injection Molding Systems |

| Krauss Maffei Injection Molding Systems | Battenfeld Extrusion Systems | Tederic Injection Molding Systems |

| Cincinatti Milacron Injection Systems | Kawaguchi Injection Molding Systems | Jwell Extrusion Systems |

| Sumitomo Injection Molding Systems | Tederic Injection Molding Systems | Fanuc Injection Molding Systems |

| Haixing Injection Molding System | FCS Injection Molding System |

![]()

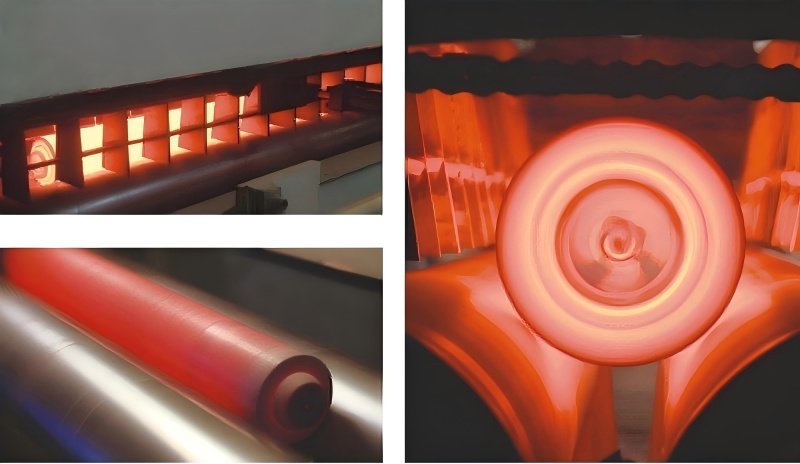

Wear-resistant Screw in bimetallic spraying proc

Screws and Tip Accessories With new TiN and TiAI

Injection molding screws after our polishing pro

Contact: Richard Wang

Phone: 15372657153

Tel: +86-15372657153

Email: info@tokindustry.com

Add: No.1807, R&D Park C Zone -12, Guanghua Road, Hi-Tech District, Ningbo, China

We chat