Base Materials: SACM645,SCM440,SKD61,SUS304, SUS316 Process: Nitrided & Bimetallic & TiN Coating Hardness: HRC55-70 Suitable for: PP, PE, ABS, PET, PVC, PS, Carbon ... Delivery time: 20 days

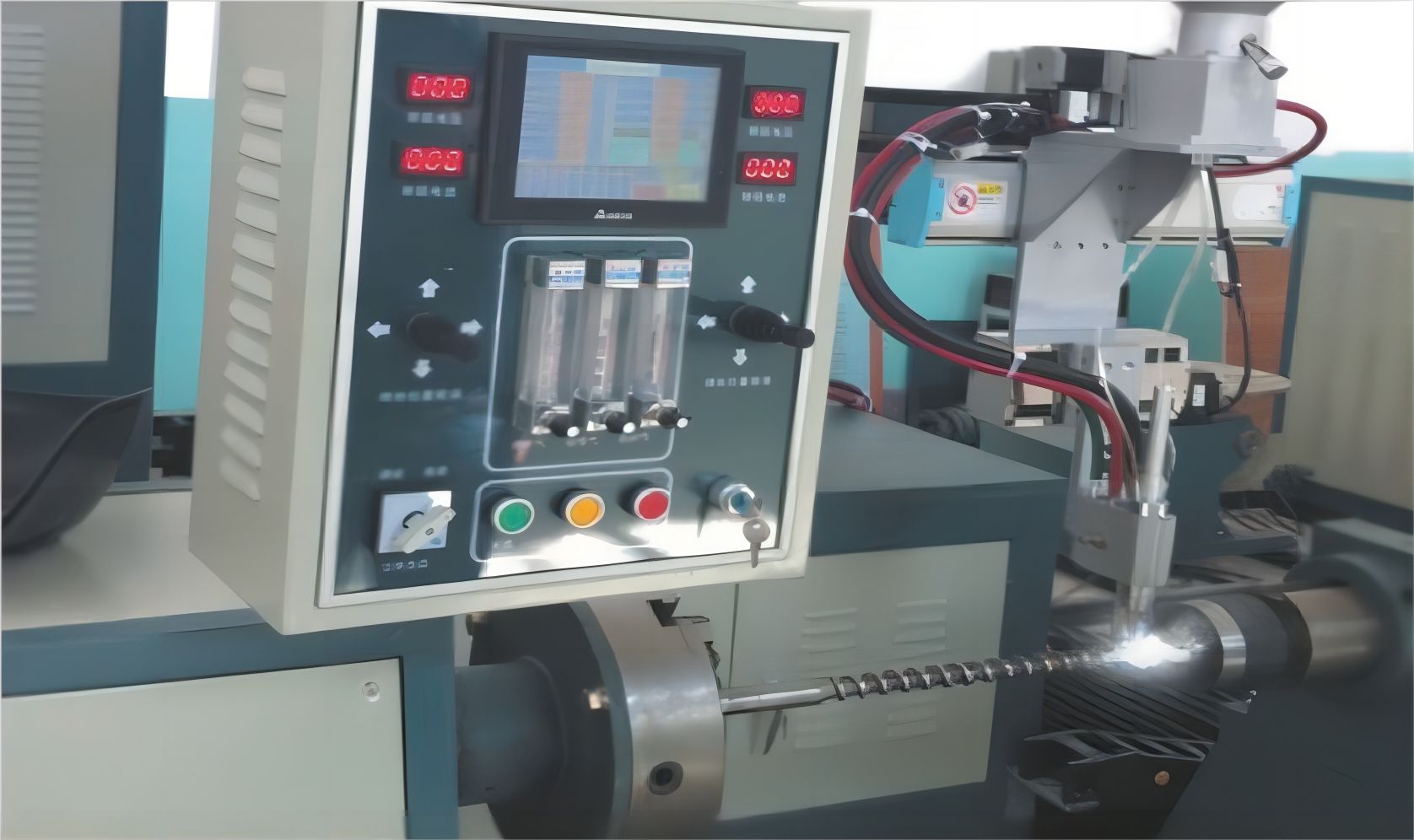

Tokin Industry specialized screw barrel is manufactured in high quality tooling steel materials: JIS-SACM645 (38CrMoala), JIS-SCM440 (42CrMo), SKD61, SKD11, SUS316, SUS304, DC53 etc., ensuring excellent mechanical properties and superior performance under extreme conditions.

Nitriding/Hardening :To Increase the hardness of screw and barrels to HRC70, that will significantly improved the wear-resistant

Chrome/TiN-Plating:With coating of chrome, that will be very helpful to corossion resistant, especially for PVC materials

Bimetallic Spraying/Centrifugal Casting: Can increase the lifespan of screw barrel better than Nitriding ( GF≥ %30)

We manufacturing and offering screw barrels for :

Haitian Injection Molding System

Haida Injection Molding System

Borche Injection Molding Systems

Battenfeld Extrusion Systems

Yizumi Injection Molding Systems

HAITAI Injection Molding System

Hwamda Injection Molding Systems

LOG Injection Molding Systems

Cincinnati Milacron Extrusion Systems

BOLE Injection Molding System

JWELL Extrusion Systems

Tederic Injection Molding Systems

Demag Injection Molding Systems

Fanuc Injection Molding Systems

Husky Injection Molding Systems

JSW Injection Molding Systems

Kawaguchi Injection Molding Systems

Krauss-Maffei Extrusion Systems

Mitsubishi Injection Molding Systems

Nissei Injection Molding Systems

Sumitomo Injection Molding Systems

Toshiba Injection Molding Systems

Toyo Injection Molding Systems

Wear-resistant Screw in bimetallic spraying proc

Screws and Tip Accessories With new TiN and TiAI

Injection molding screws after our polishing pro

Contact: Richard Wang

Phone: 15372657153

Tel: +86-15372657153

Email: info@tokindustry.com

Add: No.1807, R&D Park C Zone -12, Guanghua Road, Hi-Tech District, Ningbo, China

We chat